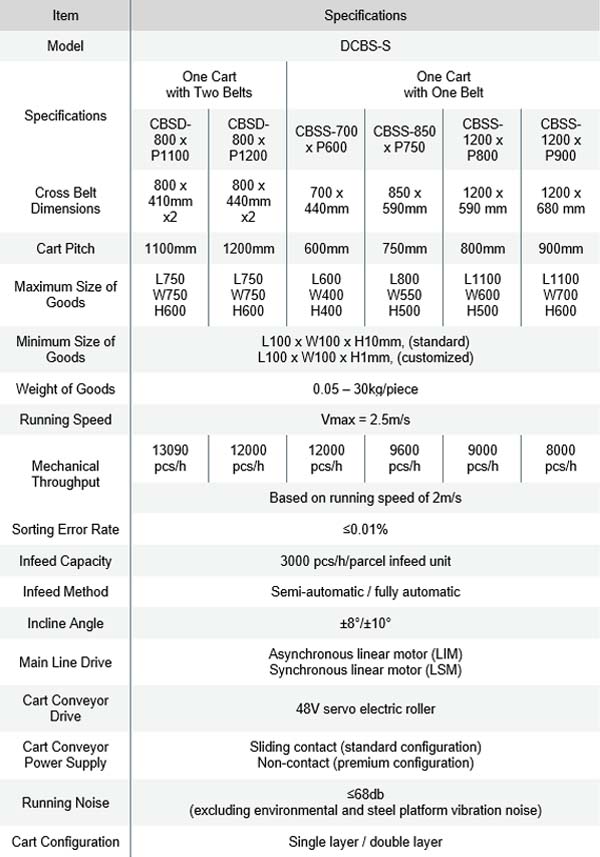

DARE DCBS-S Horizontal Cross Belt Sorter

The Damon horizontal cross belt sorter features high efficiency, low power consumption, high speed, low noise and low error rates at low cost. The sorter’s low power consumption loop drive, cross belt servo drive and low running noise achieve a sorting rate of 13,000 pieces / hour.

Features:

Cross belt servo roller drive technology

Instead of the traditional timed synchronisation drive, pulse counting ensures more accurate induction of objects onto the cross-belt sorter.

Modular quick-release construction for easy maintenance

The introduction of a modular construction design and quick release technology makes changing a cross belt car extremely convenient taking only five minutes.

Low power consumption

Compared with traditional horizontal cross belt sorters, the application of new technology including a new drive system, extremely light car body and utilising low power consumption running gear, construction, etc. reduces the energy consumption by 20%.

High speed, low noise

A perfect mix of a super light aluminium vehicle body with optimized construction and low running noise design provides a noise level under 65dB.

Cross Belt Sorter Key Components:

Key components of the horizontal cross belt sorter system include the infeed system, sorter host, outfeed system and the control system. The control system controls the induct of items from the infeed system to the sorter host for sortation. Product is sorted via the outfeed system to physical locations to complete the sorting process.

● Infeed system:

To achieve high efficiency and accurate operation of the sorter host, the function of the infeed system is to automatically measure the physical parameters and identification information of items to be sorted and to ensure items are properly and synchronously inducted onto the high speed sorting vehicles. The Damon narrow belt infeed system can provide you with customized fully automatic, semi-automatic or manual infeed systems according to your working requirements.

● Sorter host:

The sorter host is the main system component to achieve sortation with the function of delivering items to the correct sorting outfeeds according to the item’s identification information. The Damon horizontal cross belt sorter system adopts servo direct drive technology providing instant start in milli-seconds to ensure items locate in the center of the vehicle during loading as well as reducing sorting error rates during unloading.

● Outfeed system:

The outfeed system is the final stage of the sorting system. It temporarily stores the items delivered by the sorter host. At the same time, it will capture and display the related identification information of items and transmit this information to the master control system. Different types of outfeeds are available to match the diverse range of items that can be handled. Items can be directly sorted to outfeeds such as chutes, bag racks, roll cages etc. based on the size and shapes of the items to be sorted.

● Control system:

The control system is the brains of the entire sorting system. It integrates mobile power supply technology, mobile communication technology, field bus, OPC communication, Industrial Ethernet communication, PLC servo and frequency conversion technology. The control system not only controls the function of each module but also exchanges data and management policies with the upper level management system. Through this exchange, the sorting system becomes an integral part of the total logistics management system.

Click here to contact us for more information.