DARE DCBS-V Vertical Cross Belt Sorter

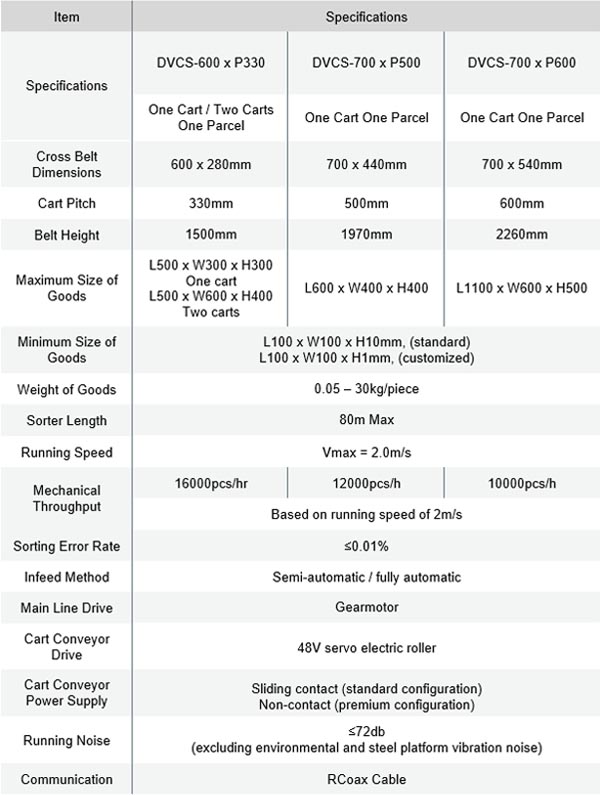

The Damon vertical cross belt sorter has a small footprint and is ideally suited to facilities where space is limited. The vertical cross belt sorter is capable of sorting items such as boxes, totes and satchels at a sorting rate of up to 16,000 p/h.

Features:

Low noise

Driven by a flexible rubber drive, the vertical cross belt sorter can run at high speeds and produces noise levels less than 72db.

Modular construction for easy maintenance

By utilising a modular design construction, maintenance can be performed quickly and easily.

Small footprint

The vertical cross belt sorter is configured in a straight line with the carts arranged in vertical closed loop which allows for a small, compact footprint.

High speed, high throughput

Capable of running at speeds up to 2.0 metres per minute, the vertical cross belt sorter can achieve sortation rates of up to 16,000 pieces per hour.

Cross Belt Sorter Key Components:

Key components of the vertical cross belt sorter system include the infeed system, sorter host, barcode scanner and outfeed chutes. Items are inducted onto the sorter via the infeed system which is available in different options. It is then automatically scanned by the barcode scanner to obtain the item’s sortation destination. The sorting host conveys the goods and sorts them to the corresponding outfeed chutes.

● Infeed system:

The package infeed system is available with semi-automatic or manual package infeed. Package infeed positions can be configured to feed from the top or side of the cross belt sorter.

● Sorter host:

The sorter host is the main system component to achieve sortation with the function of delivering items to the correct sorting outfeeds according to the item’s identification information. The Damon cross belt sorter system adopts servo direct drive technology providing instant start in milli-seconds to ensure items locate in the center of the vehicle during loading as well as reducing sorting error rates during unloading.

● Outfeed system:

Different types of outfeeds are available to match the diverse range of items that can be handled. Items can be directly sorted to outfeeds such as chutes, bag racks, roll cages etc. based on the size and shapes of the items to be sorted.

● Control system:

Using distributed leaky wave wireless communication and fast roaming technology, it can achieve instant communication and precise control of all carts no matter how long the loop is. The control system uses intelligent communication methods such as Profinet, TCP/ IP and RS485. To complete the communication between the computer and sort system, Prodave technology and OPC technology is used to provide remote intelligent fault diagnosis and maintenance.

Click here to contact us for more information.