Our Conveying & Sorting Solutions

A complete range of advanced sorter technologies with the capacity to sort in excess of 40,000 pieces per hour.

A diverse selection of roller conveyors and belt conveyors for transporting various items such as cartons, totes and satchels.

Pallet roller conveyors, pallet chain conveyors, turntables, shuttle carts, pallet stackers, pallet dispensers.

A variety of different models to provide intelligent transportation for a multitude of industries and applications.

Multi level reciprocating and continuous vertical lifts to transport cartons, totes and pallets with weight capacities from 100kg to 2000kg.

Highly efficient, fully automatic truck loading and unloading systems.

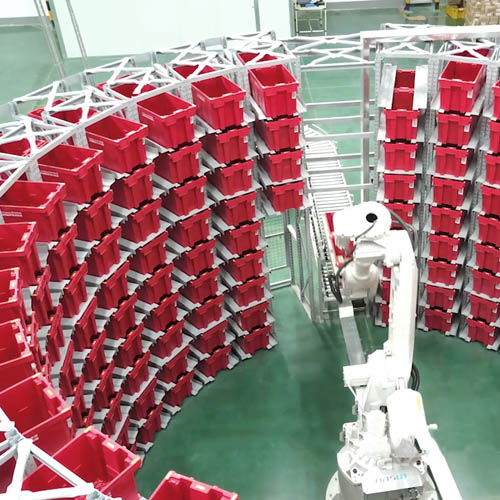

Automated solutions to provide "goods to person" storage and buffering. Dynamic pallet and carton storage systems.

Conveyor rollers to suit most applications from light duty carton handling to heavy duty pallet handling. Mounting feet, ball transfer units, omni directional wheels, carton flow track