i-Cube 3D Dynamic Buffer

The i-Cube Three Dimensional Dynamic Storage System is designed to store and handle an extensive range of products and is applicable in various environments and industries such as fast moving consumer goods, electronics, fashion, automotive and tires. All of which are based on special functional needs.

APPLICATIONS

Distribution

Case and item picking in retail and e-commerce

Consolidation buffering

Manufacturing

Intermediate buffering

Assembly buffering

Finished product storage

Postal

Pre-sorting buffer

Route consolidation

Modular Universal Design

Storage types: Tray 600 x 400mm

Tray 640 x 425mm

Tray 600 x 800mm

Tote 600 x 400 x various heights

Stacks of totes

Special types: Size on application

Max product height: 600mm

Max weight inc tray: 50kg

Max size i-Collector: L15 x W15 x H12m

ICS – CONTROL SOFTWARE

The included special i-Cube PC Control Software manages the registration of tray on dynamic locations in the system and provide an optimal choice of algorithms for moving trays in and out of the system,

The software has an interface manager which connects to all types of other systems easily including ERP/WMS, WCS, terminals, remote control, HMI, Android. Mac.

MACHINE CONTROLS CONCEPT

The mechatronic modular design offers a high level of system reliability. HMI and remote control are provided to facilitate ease of operation and fast recovery procedures.

CONFIGURATIONS

-

Plug and play module with single or double devices.

-

Single or double depends on required capacity

-

Transfer devices have one to three tray positions.

-

Vertical pitch is maximum product height + 130mm.

-

Horizontal pitch is tray length + 140mm.

-

Split level I/O.

-

I/O system works on a closed tray loop.

-

Storage strategy can be organized and/or random.

-

Tracking and tracing of trays by barcode or tags.

-

Cycles of in and out batch and/or mixed in and out batch are possible.

OPTIONAL

- Automatic inbound and outbound (I/O) connection with AGV. Transportation of trays between systems by AGV.

- Automatic tray loading and unloading.

- Interface with intelligent palletizing software. (Mixed palletizing and packing shipping cartons)

- i-Remote observer and dashboards.

- Cold store

UNIQUE SELLING POINTS

- Not only an automatic buffer but also an intelligent sequencer.

- High storage density.

- Easy size adjustment to fit into any existing building.

- Proven technology and simplicity.

- Low cost of ownership.

Click here to contact us for more information.

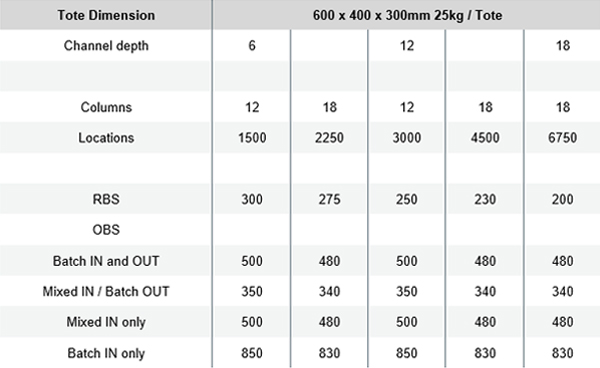

STANDARD SIZES AND CAPACITIES (Trays/hour)