Robot Mini Load

The Robot Mini Load is an automated totes warehousing system with a modular design. It provides manufacturing with an in-plant logistics service and may also be applied to e-commerce distribution centres who handle totes to provide buffering and intelligent sequencing. The system is comprised of a standard industrial robot, multi layer shelving, position and safety sensors, conveyor lines and interface with the WCS. It features unmanned operation, lower operating costs, fast delivery time, high efficiency and flexibility.

Unmanned operation:

Through the seamless connection with high level warehouse computer systems, the Robot Mini Load with its inbuilt WCS system, can perform pick and storage operations directly. The entire process is unmanned thereby saving labour costs.

Low cost:

The standard six axis industrial robot and circular shelving construction cost is only two thirds of a traditional system.

Short delivery time:

Standardized, mass production of core devices reduces the delivery time to half that of a traditional system.

High efficiency:

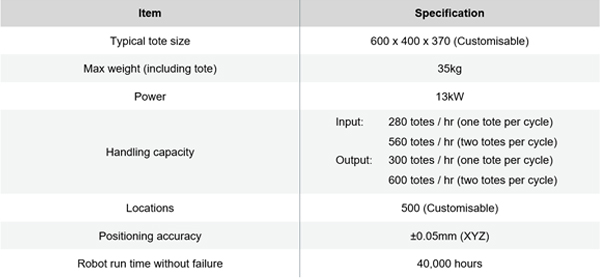

High speed operation with 380 cycles/hour. When commonly sized totes are utilized, product throughput levels of up to 280 totes/hr for inputs and 600 totes/hr for outputs can be achieved.

Flexible:

Due to its modular design, it is possible to employ parallel operation of multiple systems. It is suitable for small and medium manufacturing companies to solve problems with buffering. Large systems can be realized by parallel operation of multiple Mini Load systems.

Maintenance friendly:

The core device, the industrial robot is of standard production so technical support is readily accessible with a large number of technicians available for maintenance and service. The total cost of ownership during its lifecycle is much lower than non-standard equipment.

Click here to contact us for more information.

Specifiactions: