Driven Conveying

BELT DRIVEN

Reliable, low noise, low environmental pollution, able to run at high speed. Oily working conditions should be avoided.

Reliable, low noise, low environmental pollution, able to run at high speed. Oily working conditions should be avoided.

CHAIN DRIVEN

High load capacity. Suitable for a wide range of working environments including oil, water and high temperature however the chain is easily worn in a dusty environment. The conveying speed should not exceed 30m/min.

High load capacity. Suitable for a wide range of working environments including oil, water and high temperature however the chain is easily worn in a dusty environment. The conveying speed should not exceed 30m/min.

O-BELT DRIVEN

Conveying Load

Conveying Load

- Conveying load refers to the max load of the roller to be driven.

- Conveying load is the key point in dynamic convey.

- The load capacity of the rollers depends on the drive method and drive capacity of the O-belt. Single goods should not exceed 30 kg.

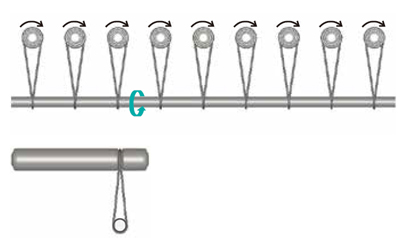

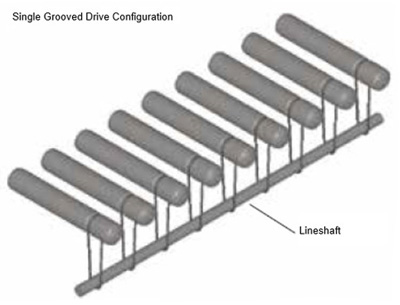

Single Groove Drive

- The driving force for each roller is transmitted separately from the line shaft. It has a higher load capacity in comparison to the double groove drive. Ideally suited for long conveyors. The maximum conveying length of each unit can be over 10 meters.

- When used in curve conveyors, the line shaft is connected by universal joint couplings.

- Maintenance is relatively difficult as you need to disassemble the entire line shaft.

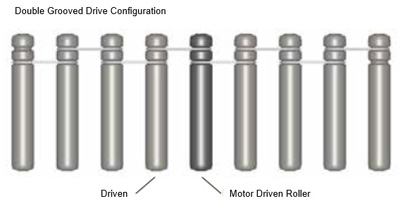

Double Groove Drive

- Simple arrangement. Easy installation and maintenance.

- The driving torque deteriorates rapidly from roller to roller. Typically, single MDR can only drive 7 to 8 rollers. The weight of single items to be conveyed should not exceed 30kg.

- The preloading value is required for the length of O-belt loop. It may vary according to the different O-belt suppliers. Please check the specifications with the O-belt supplier. Typically, reduce the preloading value by 5% - 8% from the theoretical length of loop.

Double Groove Pulley Type

- Simple arrangement. Easy installation and maintenance.

- The driving torque deteriorates rapidly from roller to roller. Typically, single MDR can only drive 7 to 8 rollers. The weight of single items to be conveyed should not exceed 30kg.

- The preloading value is required for the length of O-belt loop. It may vary according to the different O-belt suppliers. Please check the specifications with the O-belt supplier. Typically, reduce the preloading value by 5% - 8% from the theoretical length of loop.

POLY-VEE BELT DRIVE

Conveying Load

- Conveying load refers to the max load of the roller to be driven.

- Conveying load is the key point in dynamic conveying.

- The load capacity of the rollers depends on the drive method and drive capacity of the Poly-vee belt. The load rating is high when fewer rollers are driven or selecting the 3 or 4 groove Poly-vee belt.

- The load capacity for each unit can be as high as 100kg when the 3 groove poly-vee belt is used.

Roller Pitch

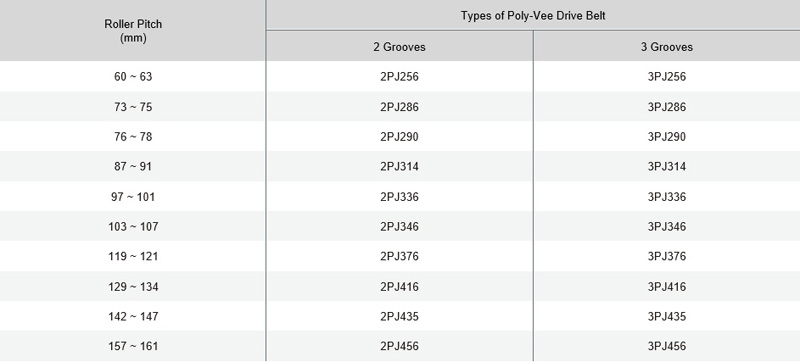

Poly-vee belt selection according to the roller pitch, please refer to the following chart:

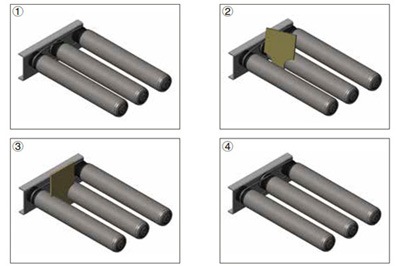

Roller Installation

To avoid incorrect installation, an appropriate method and a suitable tool is required to install poly-vee rollers.

TIMING BELT DRIVE

Conveying Load

Conveying Load

- Conveying load refers to the max load of the roller to be driven.

- Conveying load is the key point in dynamic conveying.

- The load capacity of the rollers depends on the drive method and drive capacity of the timing belt.

- The load capacity for each unit can be as high as 100kg.

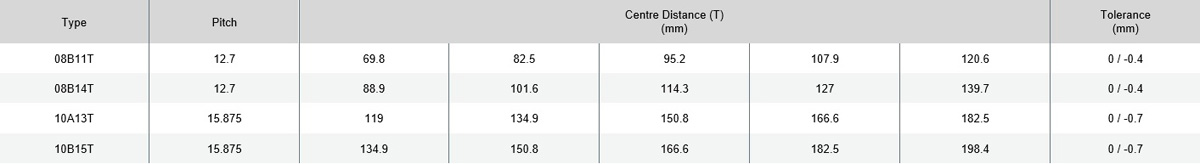

Roller Pitch

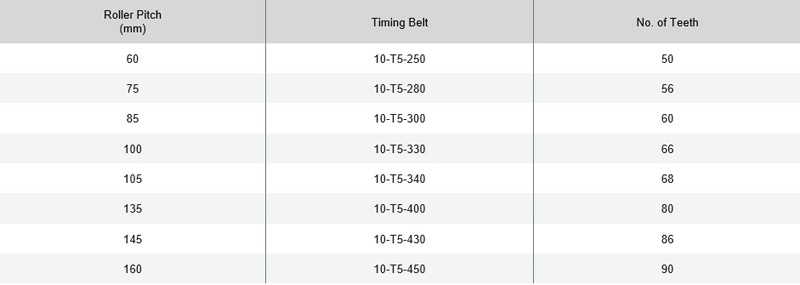

Timing belt selection according to the roller pitch, please refer to the following chart:

Timing belt selection according to the roller pitch, please refer to the following chart:

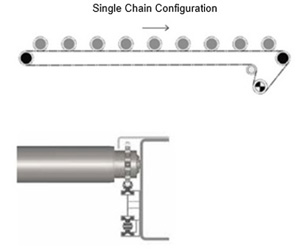

SINGLE SPROCKET DRIVE

- The compact construction is suitable for medium/low speed, continuous operation.

- Typically, the conveyor is equipped with a chain tensioner.

- When considering the maximum load of the single roller, you should also consider the ultimate tension of the chain under conveyor full load conditions.

- Compared with the double chain drive, the choice of roller pitch is more flexible and not determined by the chain pitch.

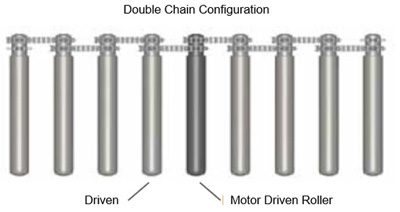

DOUBLE SPROCKET DRIVE

- Suitable for heavy duty loads and frequent start/stop operation.

- To obtain the best roller drive transmission, the drive should be located in the centre of the conveyor.

- Compared with single sprocket drive, the conveying speed is higher. Maximum speed: 30m/min.

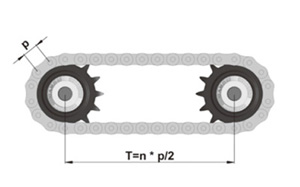

- The roller pitch is limited, please see below.

T = n x p/2

Where:

n - integer (1, 2, 3, etc.)

p - chain pitch

n - integer (1, 2, 3, etc.)

p - chain pitch

Avoid half pitch chain. Please use the chart below for the chain pitch.